By Victoria Waldersee and Nadine Schimroszik

Summary

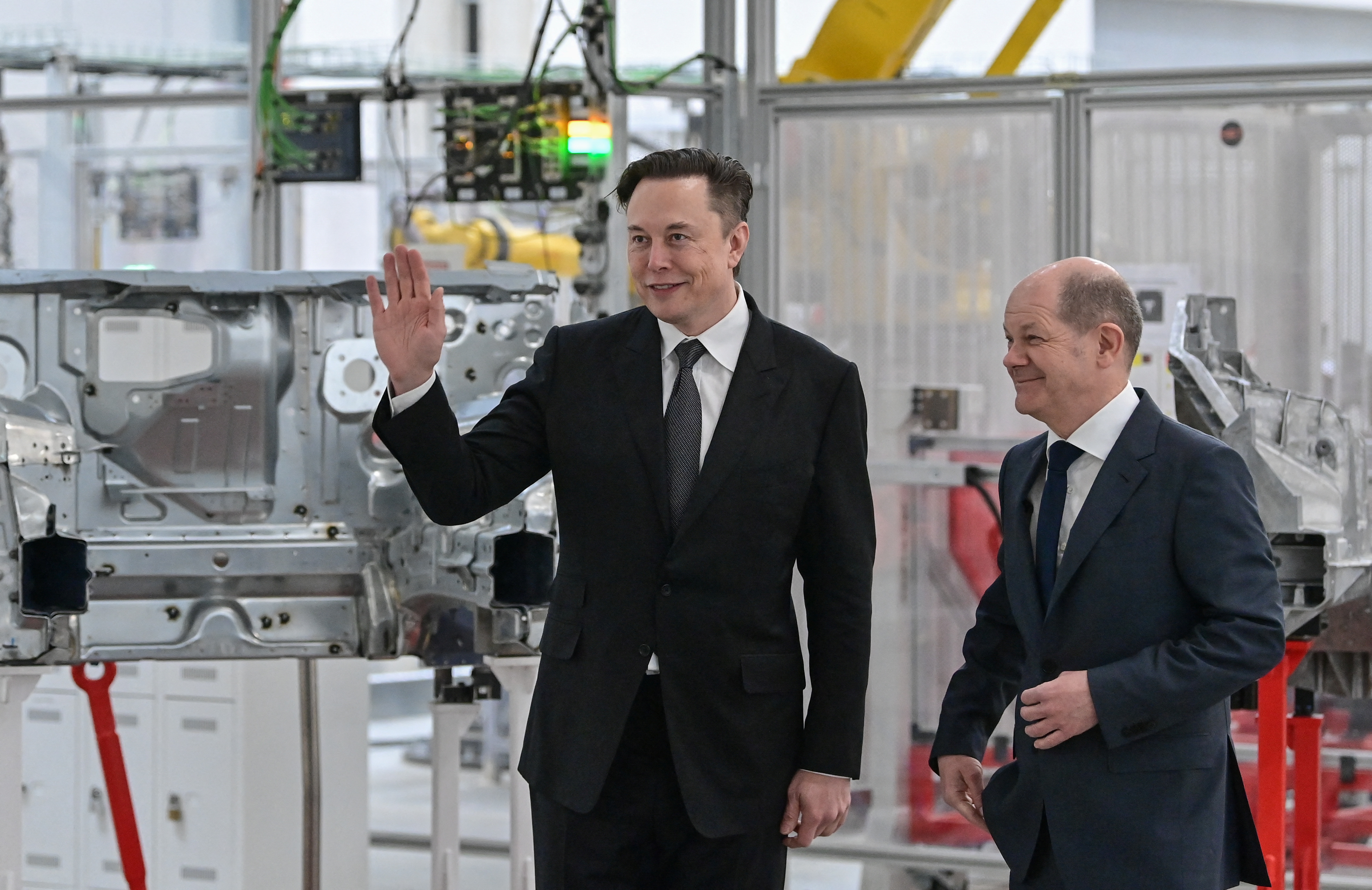

GRUENHEIDE, Germany, March 22 (Reuters) – Elon Musk was cheered as he oversaw the handover of Tesla’s (TSLA.O) first German-made cars at its Gruenheide plant on Tuesday, marking the start of the U.S. automaker’s inaugural European hub just two years after it was first announced.

Loud music played as 30 clients and their families got a first glimpse of their shining new vehicles through a glitzy, neon-lit Tesla branded tunnel, clapping and cheering as Tesla Chief Executive Musk danced and joked with fans.

Musk said that Tesla is likely to launch a test version of its new “Full Self-Driving” software in Europe, possibly next year depending on regulatory approval.

“It’s quite difficult to do full self-driving in Europe,” he told factory workers on Tuesday, saying much work needs to be done to handle tricky driving situations in Europe where roads vary a lot by country.

Two protestors abseiled from a motorway sign near the factory, blocking traffic for hours after the event.

Musk had hoped to begin output from the factory eight months ago, but licensing delays and local concerns around the plant’s environmental impact held up the process.

It got the final go-ahead from local authorities on March 4 to begin production in Germany, provided it met conditions ranging from its water use to air pollution controls.

The plant opening came on the same day as the top U.S. securities regulator urged a federal judge not to let Musk back out of an agreement requiring that his Twitter use be monitored. read more

RACE WITH VW

The new owners received the Model Y Performance configuration, a vehicle costing 63,990 euros ($70,500) with a 514 km (320 miles) range, Tesla said, adding that new orders from the plant could be delivered from April.

Tesla said that around 3,500 of the plant’s expected 12,000 workers have been hired so far.

At full capacity, the plant will produce 500,000 cars a year, more than the 450,000 battery-electric vehicles that German rival Volkswagen (VOWG_p.DE) sold globally in 2021.

It will also eventually generate 50 gigawatt hours (GWh) of battery power, surpassing all other plants in Germany. Tesla is expected to initially import batteries from China for its German-made Model Ys before it starts local battery production.

Musk said on Tuesday that battery production will be a “challenge” next year and will be “the limiting factor” in the coming years, as Tesla aims to aggressively boost vehicle production.

For now, Volkswagen still has the inside track in the race to electrify Europe’s fleet, with a 25% market share to Tesla’s 13%. Musk has said ramping up production would take longer than the two years it took to build the plant. read more

JPMorgan predicted Gruenheide would produce around 54,000 cars in 2022, increasing to 280,000 in 2023 and 500,000 by 2025.

Volkswagen, which has received 95,000 EV orders in Europe this year, is planning a new 2 billion euro EV factory alongside its existing facility in Wolfsburg and six battery plants across Europe.

But its timeline lags Tesla’s, with the EV factory due to open in 2026 and the first battery plant in 2023.

($1 = 0.9086 euros)